I. Introduction

What would you think if you frequently heard a small scrap overlooked in the automotive exhaust system which is valued surprisingly more than gold? That may sound a bit unbelievable, but absolutely true when it comes to catalytic converters.

Treasure actually hides inside these plain-looking metal casings that holding the most precious elements including platinum (Pt), palladium (Pd) and rhodium (Rh). These metals are essential for reducing vehicle emissions, making automotive catalysts exceptionally valuable. Thus, they are not trash but a precious “urban ore” waiting to be mined.

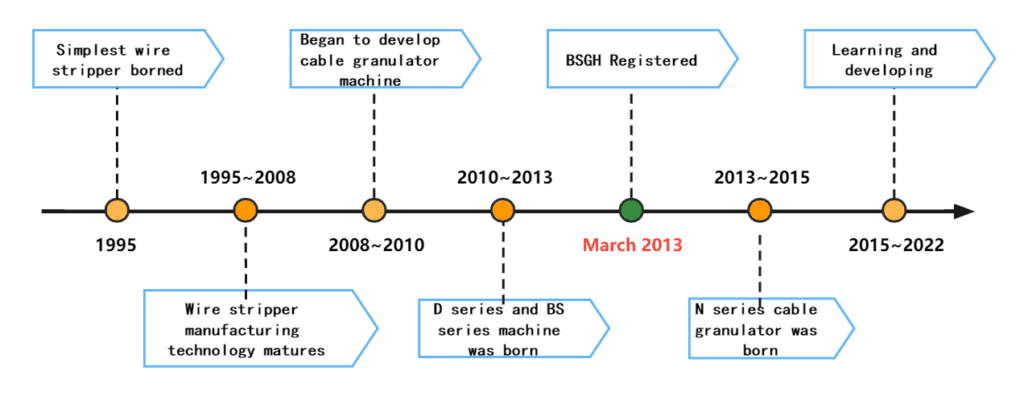

With three decades of market leadership in recycling, BSGH company has possesses extensive experience and industry expertise. We are committed to making specialized guides about car catalytic converter recycling and hope they can help you make more profit.

This comprehensive handbook about recycling catalytic converters covers everything you need to know — from profitability analysis to optimized recycling methods. It will prove invaluable whether you are running a scrapyard, an auto dismantling station or simply exploring new opportunities.

II. Can recycling catalytic converters bring you the ideal profit?

Let’s analyze the profit of scrap catalytic converters from four aspects:

1. Expanding Sustainable Supply

There are millions of scrap cars worldwide, resulting in a continuously growing volume of waste catalytic converters. Therefore, such a large amount of used vehicles annually can offer a never-ending resource for catalytic converters recycling.

2. Quick Profit

You can make an instant profit after selling catalytic converters in whole. The global price can reach $70 — $130 per unit on average. Prices vary according to different vehicle brands and models — Toyota Prius’s catalytic converters is more valuable due to high-density noble metal content. As a result, you are able to generate a reliable cash flow.

3. Real Treasure: Noble metals Recovery

Ceramic honeycombs actually holds the true value of catalytic converters. Specifically speaking, honeycombs are coated with a thin layer of the rarest and most precious metals on Earth – platinum group metals (PGMs) including platinum (Pt), palladium (Pd) and rhodium (Rh). You can extract 0.2 to 5 grams of PGMs from a kilo of catalyst material relying on their types and qualities.

Let’s list in a form (Note: prices vary with market conditions) :

| PGM | Price |

| Platinum (Pt) | $30 to $50 per gram |

| Palladium (Pd) | $25 – $45 per gram |

| Rhodium (Rh) | $180 – $200 per gram |

In summary, recycling PGMs from car catalysts obtains more profits than selling the entire catalyst.

4. Invest for Future

The global need for PGMs shows signs of boosting. Internal Combustion Engine Vehicles (ICEVs) will continue to dominate the automotive sector in the coming years. However, stricter emission regulations will promote increased demand for platinum group metals (PGMs) among high-efficiency catalytic converters. These noble metals are also necessary in electronics and green hydrogen production, further enhancing their long-term value. PGM prices are likely to remain high or even higher with the increasing demand and limited supply. In a word, no matter you are a manufacturer, a distributor or a processor, there is no doubt that recycling catalytic converters represents a highly profitable business with bright future.

III. From Scrap to Wealth: A Step-by-Step Recycling Process

Above all, believe you are fully aware of the market value of catalytic converters. But how to turn them into pure, marketable and precious metals? Here’s a professional workflow:

Step 1: Proper Handling & Dismantling (Safety First!)

Safety always comes the first. When removing the converter from a vehicle, please wear Personal Protective Equipment (PPE), including chemical-resistant gloves and safety goggles. The converter can be unbolted or cut from the exhaust pipe with a reciprocating saw. As a consequence, the used catalytic converters retain their full value.

Step 2: Identification and Classification

Not all converters are created equal. Most have serial numbers on their shells. This code can be cross-referenced with databases that specify its PGM content. Whether you sell it in whole or process it further, it is vital to evaluate your catalytic converter content accurately, just classifying converters based on OEM, aftermarket and car models. Thus, a precise grading of catalytic converters increases their resale value.

Step 3: Decanning – Removing the Honeycomb

It is called decanning to extract the PGM-coated honeycomb ceramic of a converter from its protective steel shell. Then the specialized equipment like our Catalytic Converter Recycling Machine plays a crucial role in efficiently recycling PGM. Equipped with a large, sharp and durable blade, our catalytic converter cutting machine can cut the steel shell with consistent cutting performance, significantly reducing labor costs. The dust collection system captures any precious metal particles released during shearing and ensures zero PGM loss. Lastly, you can manually separate the honeycomb core.

Step 4: Crushing and Screening

Once you get the ceramic cores, the next step is to granulate ceramic cores into ultra-fine and high-purity powder, maximizing the surface area for the chemical extraction process. Then the crushed material experiences a precise screening to remove contaminants such as insulating mats, metal fragments and rust, so that you can obtain a kind of purer and high-concentration platinum group metal (PGM) powder that serves as the raw material for the final extraction process.

Step 5: Smelting – High-Tech Treasure Hunting

The PGM-enriched powder is mixed with a “collector metal” (e.g.copper or iron) and heated to extreme temperatures in a furnace. The PGMs dissolve into the molten collector metal, forming a high-value alloy. The remaining ceramic and other impurities produce a glassy waste layer called “slag” – the industrial waste to separate and discard.

Step 6: Chemical Processing and Refining

The final refining stage is also the most technically complex phase and exclusively conducted by specialized PGM refineries due to its precision requirements. You can utilize advanced hydro-metallurgical processes (including acid leaching and electrolysis) to chemically dissolve precious metals and separate them from collector metals. The purity rate can reach as high as 99.9% or even higher by using this refining technology to process platinum, palladium and rhodium. The final output metals completely meets global standards for trading and offers an instant cash flow.

IV. Conclusion

It is a wise investment to recycle catalytic converters. These PGM-rich components found in almost every vehicle not only hold a significant value but also represent a greater potential for future. From proper handling, sorting, decanning, crushing, smelting to chemical refining, every recycling process plays a crucial role in maximizing your profit. With the tailored equipment like a professional catalytic converter recycling machine and excellent recovery workflows, scrap materials can be transformed into high-yield assets by you, surely this process needs to be done under a professional specialized recycling company.

As a specialist in catalytic converter recycling equipment, our BSGH company has the ability to provide end-to-end solutions for PGM recovery. Contact our experts for technical consultations or customized recommendations.

Tags: car recycling, hammer mill, car starter recycling, @scrapyards, @recycling