Ⅰ. Introduction

Radiators are essential in many fields such as automobiles, air conditioning systems, and industrial machinery. Since they contain many high-value metals such as copper, aluminum, and iron, radiators still have great economic value even after their service life ends. Recycling copper, aluminum, and other metals from waste radiators allows these valuable materials to be reused in production, reduces dependence on new resources and manufacturing costs, and brings high economic benefits to recyclers. It is an ideal business that can achieve win-win results.

BSGH Granulator radiator recycling machine is specially designed for recycling various radiators. Our machine can efficiently separate copper tubes, aluminum, iron, and other metals from waste radiators. The purity of the recycled metal can reach 100%, with a higher sales price. This article will introduce in details of types of radiators that can be recycled, as well as the methods and machines used for recycling them.

Ⅱ. Recyclable radiator types

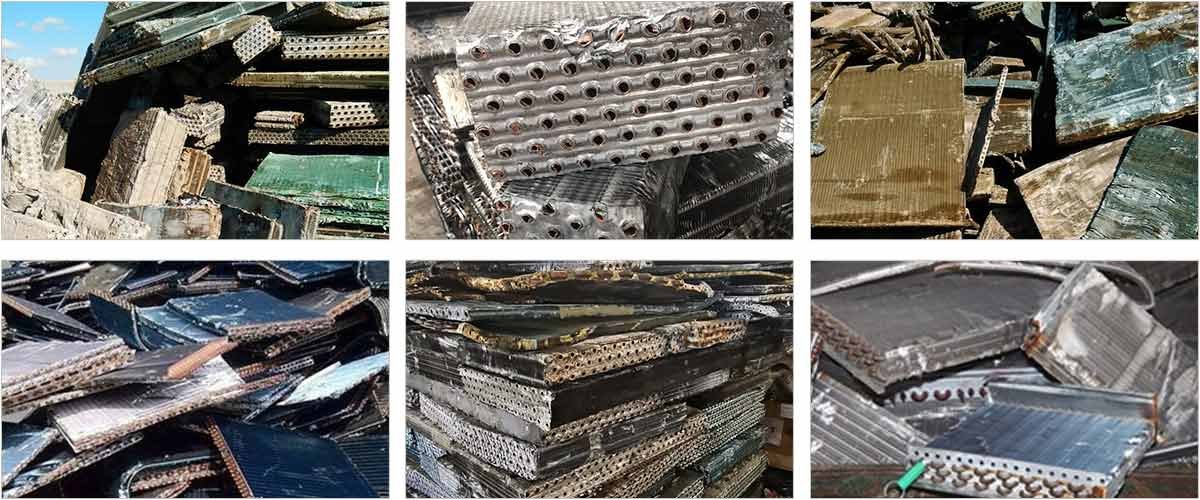

There are many types of radiators, each with different recycling values and recycling methods. So, which radiators can be recycled? In this chapter, we will introduce the 5 most common types of recyclable radiators.

1. Air conditioner radiator

Air conditioner radiators are usually made of copper and aluminum. Copper is often used for heat pipes based on its excellent thermal conductivity, and aluminum is often used for heat sinks due to its light weight and good conductivity. The combination of copper and aluminum not only achieves efficient cooling performance but also increases its recycling value.

2. Refrigerator Radiator

Refrigerator radiators help regulate the unit temperature by dissipating heat that escapes from the interior. They are typically made of copper tubing and aluminum fins, materials that are specifically chosen to support the refrigerator’s continuous cooling cycle.

3. Car Radiator

Car radiators play a vital role in the vehicle’s cooling system, dissipating heat from the engine to prevent overheating. Car radiators are designed to be more durable than home radiators, and aluminum is often used for the fins and core because it is lightweight and has the ability to dissipate heat. Some models include copper tubing to enhance thermal conductivity and improve overall cooling. When car radiators are no longer functional, they can be recycled to produce valuable aluminum and copper materials ideal for industrial applications.

4. Water tank radiator

Water tank radiators are often used in industrial or large cooling systems and are an essential component of systems that require continuous cooling. This type of radiator is usually made of high thermal conductivity metals (such as copper or aluminum), which have high durability and efficient heat dissipation. When their service life ends, copper and aluminum materials have significant recycling value and can be reused through recycling.

5. Aluminum clad iron radiator

Aluminum clad iron radiator refers to a radiator with an aluminum skin wrapped around an iron tube, which is widely used in electronics, automobiles, aerospace, and other fields. The solid iron core provides a stable structure for this radiator, while the aluminum coating helps to dissipate heat quickly.

Ⅲ. Recycling methods and professional equipment for different types of radiators

BSGH Granulator mainly divides various radiators into three types according to recycling methods: flat, regular, and non-bent radiators, aluminum-clad iron radiators, and curved and irregular radiators. We have developed and manufactured special recycling equipment for each type of radiator, which can separate copper, aluminum, iron, and other metal materials from waste radiators to meet the recycling needs of almost all types of radiators on the market. Next, we will introduce you to the recycling method of each type of radiator in combination with our professional radiator recycling machine.

1. Flat, regular, and non-bending radiator

The recycling method for this type of radiator is the simplest. We mainly have two models for processing: BS-1200P and BS-1200S. Both machines can directly process 1-2 layers of waste radiators. If you need to process more than 2 layers, please use a band saw to cut them into 1-2 layers first, and then use our machines to recycle them easily.

BS-1200P radiator recycling machine

This machine is specially designed for recycling waste radiators. It is mainly composed of a frame, 2 motors, 2 reduction boxes, a feed panel, a cutting part, a transmission part, and a material separation part. Its copper tube center distance is 19mm, 21mm, and 25mm (if you have radiators of other sizes, we can customize them for you), and the processing capacity can reach 3T/Day. BS-1200P can efficiently separate copper tubes from aluminum foil. There will be no loss of copper and aluminum during the recycling process, and the purity of the recycled material can reach 100%.

BS-1200S radiator separator machine

Compared with the BS-1200P radiator recycling machine, the BS-1200S standard machine adds 2 more inlet feeding panels and more functionality. The BS-1200S radiator recycling machine is an improvement and upgrade based on the BS-1200P. Two more feeding panels were added, and the processing capability was also increased. Its copper tube center distance is 17.5mm, 19mm, 21mm, 22mm, and 25mm (copper tube center distance supports customization), and the processing capacity can reach 4T/Day.

Both BS-1200P and BS-1200S radiator recycling machines are easy to operate, the operator only needs to perform simple feeding operations. When feeding, push the radiators of different specifications into the feed port of the corresponding size. The left side of the radiator copper tube must touch the left side of the feed port, or the right side of the radiator copper tube must touch the right side of the feed port. When the radiator enters the machine, the machine will automatically complete the copper and aluminum separation process and send the final product out from the discharge port.

The following video will show you how we deal with flat regular radiators

2. Aluminum-clad iron radiator

Aluminum-clad iron radiators are made of special materials and are difficult to process with ordinary radiator recycling machines. BSGH Granulator has specially designed two recycling machines specifically for aluminum-clad iron radiators, which can easily separate the iron tube and aluminum foil without material loss and high processing efficiency.

BS-ACS20 aluminum clad iron radiator stripping machine

The BS-ACS20 radiator recycling machine is mainly composed of a frame, a motor, a reducer, and two power shafts. It can process the diameter of the iron pipe in the radiator within the range of 20mm, 22mm, 25mm, and 27mm. The BS-ACS20 aluminum-clad iron radiator recycling machine has stable performance and powerful functions. It can quickly and thoroughly separate the aluminum pipe and the iron pipe to obtain pure aluminum and pure iron, ensuring that the recycling process is both efficient and environmentally friendly.

Radiating pipe stripping machine

This machine can efficiently separate the iron pipe and aluminum foil from the waste aluminum clad radiators, and the separated iron pipe still keeps its original shape and aluminum foil in block shape, which greatly improves the recycling rate. It has high processing efficiency, simple operation, and easy maintenance, which greatly saves manpower and material resources and reduces production costs. Radiating pipe stripping machines can not only process aluminum-clad iron radiators with iron pipe diameters ranging from 16-35mm but also process waste cables with diameters ranging from 20 to 60mm. Its powerful functions have made it popular and praised by customers all over the world since its launch.

The following video will show you how we deal with aluminum-clad iron radiators:

3. Curved and irregular radiators

Curved and irregular radiators are more difficult to recycle, but our BS-ACP1000 large radiator recycling line can efficiently recycle such radiators through the crushing and separation process. In addition, BS-ACP1000 can also directly process multi-layer radiators without pre-treatment. Its powerful processing function makes it the best choice for recyclers with a large number of radiators.

BS-ACP1000 radiator recycling plant

BS-ACP1000 is a large-scale radiator recycling line that integrates automation and high efficiency. It uses the most advanced crushing and separation technology, which can quickly decompose waste radiators into valuable materials. BS-ACP1000 radiator recycling plant is equipped with a pre-crusher, a main crusher, two airflow separators, two magnetic separators, and a dust removal system. The daily processing capacity is as high as 20-30t, which greatly improves the recycling efficiency of waste radiators. Advanced airflow separation technology supports our machines to quickly separate copper tubes and aluminum foils, and the magnetic separator can absorb iron from all materials, so that our machines can maximize the recovery of copper, iron, and aluminum from various waste radiators, with almost no metal loss, a recovery rate of up to 99.99%, and the purity of the recovered metal is as high as 100%, which can be sold at a high price.

The following video will show you how we deal with curved and irregular radiators:

Ⅳ. Advantages of BSGH Granulator Radiator Recycling Machine

BSGH Granulator specializes in the research, development and production of copper recycling equipment. Our radiator recycling machine has a high reputation in the market and can effectively separate copper, aluminum, and other metal resources from waste radiators. Compared with other radiator recycling machines on the market, our machine has the following advantages:

Advantage 1:

Our machine adopts a vertical crushing structure, which can directly feed and crush various radiators on the market. Compared with the traditional production line, it can not only greatly reduce the situation of aluminum-clad copper, but also effectively reduce the later recycling cost, achieve more efficient material separation, and increase the copper recovery rate.

Advantage 2:

The machine is made of high-strength materials and durable, it undergoes strict quality inspections before leaving the factory to ensure that your machine can operate efficiently. Even after long-term operation, our machine can still maintain stable performance and provide reliable support for your recycling business.

Advantage 3:

Our machine has a simple structure, low maintenance requirements, and low energy consumption. The recycling process only requires one operator, which greatly reduces your operating and maintenance costs. The final product is high-quality and high-purity copper with low loss. Copper, iron, aluminum, and other metals can maintain their original appearance and can be sold at a higher price. Through lower costs and higher sales prices, our radiator recycling machine can help you maximize your profits.

Advantage 4:

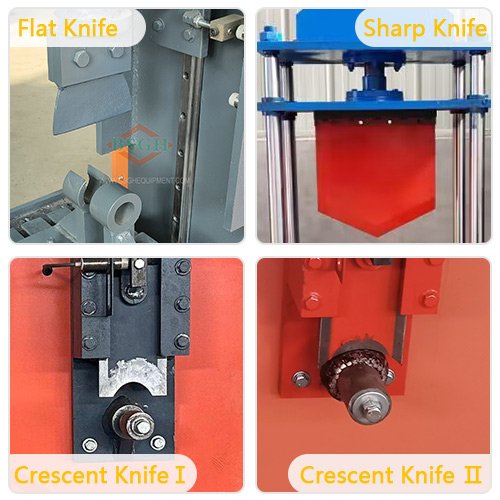

We can provide you with a wide range of flexible customization options. Based on your different raw materials, our professional designers can quickly help you design the solution that best suits your needs. Whether you want to customize the copper tube center distance, voltage, blade material, accessories, or machine color, or size, the solutions we propose will far exceed your expectations on both quality and price.

Ⅴ. Applications of BSGH Granulator Radiator Recycling Machine

BSGH Granulator radiator recycling machine is widely used in various industries, including scrap recycling, metal recycling, radiator manufacturing, etc.

Waste Recycling:

- Used in waste recycling centers to recover valuable materials from waste radiators and achieve efficient reuse of resources.

Metal Recovery

- Dedicated to recovering valuable metals such as copper, aluminum, and iron, meeting the metal industry’s need for sustainable resources.

Radiator Manufacturing

- If you manufacture all kinds of radiators, by recycling these scrap radiators, you can obtain the metal raw materials needed to produce new radiators from waste radiators, reducing production costs and thus increasing profits.

By using our radiator recycling machines, these companies can efficiently recycle metal materials from waste radiators, which can not only generate profits and reduce production costs but also achieve the recycling of resources and protect the environment.

Ⅵ. Conclusion

Recycling used radiators can bring both environmental benefits and significant economic value. However, radiators of different materials and structures require different recycling methods, you can use our machine to recycle various types of radiators, covering almost all radiator types, and can provide you with advanced functions and powerful processing capabilities. Using our radiator recycling machine, not only achieves fully automated production and greatly improves production efficiency, but also effectively reduces costs and obtains higher profits.

If you are interested in our equipment, please feel free to contact us, we look forward to sharing more details, pictures, and videos of the machine with you.

Contact Jocy: + 008613772508206