Ⅰ. Introduction

With the increasing awareness of environmental protection and the growing demand for resource recycling, the recycling industry is gradually becoming an important force in the economy. Among the many recyclable materials, copper has attracted much attention due to its high value and wide application. As an efficient recycling machine, the cable granulator can process various kinds of scrap cables, is of great significance to improving the scale and profitability of the recycling business.

This article will explore why you can invest in a cable granulator to help you get greater returns.

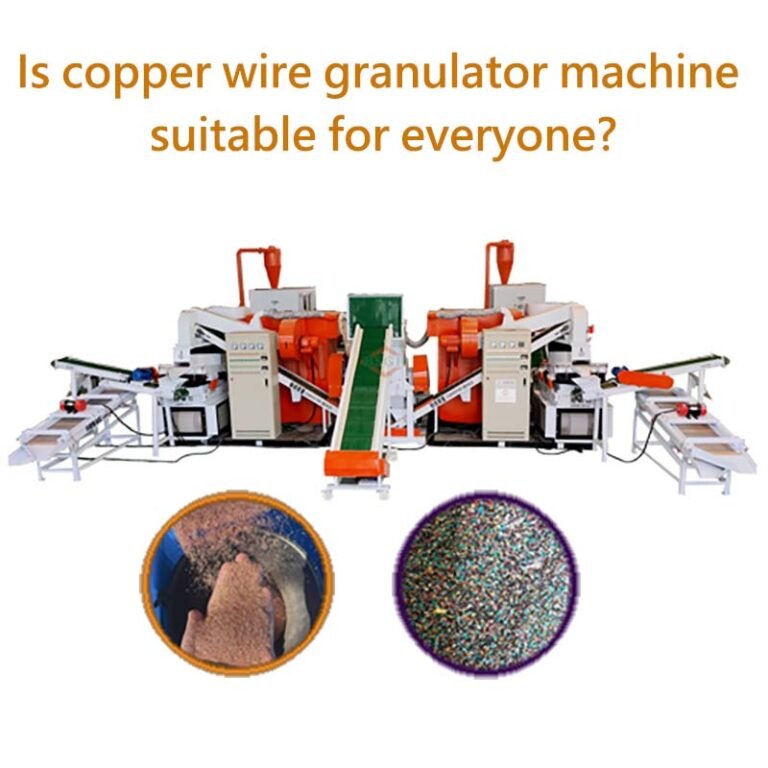

1. Cable Granulator Overview

The cable granulator is a machine used to crush scrap wires and separate copper from plastic, mainly used to process scrap wires and cables. By separating metal from plastic, it can achieve pollution-free treatment of scrap wires and cables, effectively solving the environmental pollution problem caused by traditional scrap wire separation and recycling methods.

2. The Importance of Cable Granulator

In today’s era of increasing environmental awareness, cable granulators, as highly efficient recycling equipment, have become an indispensable part of the scrap wire recycling business. Through advanced recycling technology, cable granulators can effectively separate copper and plastic from scrap wires, which can not only improve the recycling rate of copper but also bring considerable economic benefits to enterprises.

Ⅱ. Working Principle of Cable Granulator

First, let’s learn about the structure and working process of cable granulators.

1. The main components of the cable granulator

Our cable granulator mainly consists of a Pre-shredder, Main Crusher, Air Separator, Conveyor Belt, Vibrating Table, Magnetic Separation, Electrostatic Separation and Dust Collection. The pre-shredder, conveyor belt, magnetic separation and electrostatic separator are optional devices, all of them can work independently, and you can equip them with your production needs, helping you improve production efficiency and save labor time and costs.

2. How does the cable granulator separate scrap wire into pure copper and plastic?

First, the scrap wires and cables are put into the pre-shredder for preliminary crushing, then the main crusher as secondary crushing, shred the copper plastic mixture into 3-5mm granules. After the copper-plastic mixed granules are conveyed to the next components, they are separated by the airflow separator and the small vibrating table respectively to obtain pure copper and plastic.

The Airflow Separator, for the first separation, sorts the copper and plastic particles through the different weights of copper and plastic.

The vibrating Table is connected after the copper outlet and plastic outlet for secondary separation. It mainly uses the vibration frequency to achieve separation.

When the two steps of separation are finished, you will get pure copper and plastic granules.

Ⅲ. Why Should You Invest In A Cable Granulator?

After knowing about the basic knowledge about cable granulators, let’s talk about why should you invest in a cable granulator.

1. Improve recycling efficiency

The cable granulator efficiently separates copper from plastic in scrap wires and cables, maximizing copper recovery while minimizing plastic pollution. Its high recovery rate is a result of advanced technology, ensuring effective resource reclamation and environmental protection.

Through physical separation, it avoids the environmental pollution of traditional combustion treatment and achieves energy conservation and environmental protection. The cable granulator can effectively extract valuable metals and plastic materials from scrap wires and cables, thereby realizing the recycling of resources.

In addition, the operation of the cable granulator is simple and efficient, the intelligent control system makes the operation process more convenient, and the high-speed rotating blades and sorting devices improve the processing efficiency, further ensuring the realization of a high recovery rate.

2. Increase Corporate Profits

Since the price of copper is relatively high, processing scrap wires and cables through a cable granulator can effectively recover the copper and other valuable materials, thus achieving significant economic benefits. In addition, the cable granulator has efficient processing capabilities, which can improve production efficiency, allowing companies to process more scrap wires and cables in a short time, thereby obtaining a faster return on investment.

The purity of the copper material processed by our cable granulator can reach 99.9%, and the recovered copper can be directly used to produce various copper products or sold. As the upgrading of electronic products accelerates, the generation of scrap wires and cables is also increasing, which keeps the market demand for copper materials stable and helps enterprises achieve stable sales.

These factors will bring considerable profits to the enterprise and promote its scale expansion. In addition, the efficient operation of the cable granulator can also improve the overall profitability of the enterprise, giving it an advantage in the fierce market competition.

3. Reduce Corporate Costs

First of all, the cable granulator uses excellent separation technology to quickly and accurately separate copper and plastic. This efficient separation process significantly reduces the need for manual separation, thereby improving processing efficiency, allowing enterprises to process more scrap wires and cables in the same time, effectively reducing labor costs and time costs.

Moreover, the cable granulator does not produce harmful substances during the production process and meets environmental protection requirements, which avoids additional costs caused by violating environmental regulations. Furthermore, the cable granulator uses advanced technology to effectively reduce production costs, including reducing energy consumption and improving raw material utilization efficiency, thereby further reducing corporate operating costs.

At the same time, since the cable granulator realizes automated operation, the skill requirements for operators have been reduced, which further reduces operating costs.

Ⅳ. Investment Return Analysis of Cable Granulator

Next, I will give you a comprehensive investment return analysis from the initial investment cost, operating cost and return on investment of the cable granulator.

1. Initial investment cost of cable granulator

The initial investment cost of the cable granulator includes equipment purchase costs, installation costs, site costs, etc. And the initial investment costs of cable granulators of different models and functions will also be different.

Equipment Purchase Cost

This is the largest part of the initial investment, including the price of the cable granulator itself and the auxiliary equipment that may be needed, such as conveyor belts, separation devices, etc.

Installation Cost

Including equipment installation, commissioning and possible infrastructure construction costs, such as electricity, etc.

Site Cost

Depending on the size and production capacity of the cable granulator, the cost of renting or purchasing a site needs to be considered.

2. Cable granulators operation costs and maintenance costs

The operation cost and maintenance cost are also important factors to be considered in the investment and operation process of the cable granulator. The following are some of the main costs:

Raw Material Cost

The main raw material of the cable granulator is scrap wire and cable, which needs to be purchased or collected. The price of raw materials will fluctuate due to market supply and demand, regional differences and other factors.

Labor Cost

The operation, maintenance and management of the cable granulator requires a certain number of employees. Labor costs include employee wages, benefits and training costs.

Maintenance and repair costs

The cable granulator may malfunction or wear out during operation and require regular maintenance and repair. Maintenance and repair costs include the cost of replacing parts, lubricants and other consumables.

3. Profit Analysis of Cable Granulator

By calculating the operating cost and expected benefits of the cable granulator, its return on investment can be obtained. Generally speaking, the return on investment of the cable granulator is high and the cost can be recovered in a relatively short time.

You can refer to the specific profit analysis of the cable granulator business below(take the big cable granulator model BS-ECO1000 for example):

| Running Cost Per Day($) | |||

| Input | Scrap Car Wires | Power Consumption | Workers |

| Quantity | 8T | 76KW/H*8H*0.7=425.6 | 2 workers |

| Unit price | 4691/T | 0.14 | 50/Day |

| Input cost | 37528 | 60 | 100 |

| Total cost | 37688 | ||

| Income Per Day($) | ||

| Input | Copper | Plastic |

| Quantity | 8*55%=4.4T | 3.6T |

| Price | 10008/T | 300/T |

| Income | 44035.2 | 1080 |

| Total income | 45115.2 | |

Daily Profit = USD 45115.2– USD 37688= USD 7427.2

Through the above analysis, you can clearly see that investing in a high-quality BSGH cable granulator is a very profitable business. This machine not only helps to produce high-quality copper granules in large quantities but also reduces labor costs.

Tips: The data in these tables are only for reference. You can use the elements in the table to calculate the profit based on your exact data.

Ⅴ. Market Demand and Trend of Cable Granulator

So, what is the development status of the cable granulator? I will analyze the market demand and trend of cable granulators for you. After understanding this, I believe you will be more willing to invest in a cable granulator.

1. The demand for cable granulator in the global recycling market

As the world pays more attention to environmental protection and resource recycling, the market demand for cable granulator continues to grow.

The main reasons include the following:

Large Market Demand

With the increase in global environmental awareness and the increase in the number of scrap wires and cables, the market demand for cable granulator, as an important equipment for the recycling and reuse of scrap wires and cables, has increased significantly. Through efficient physical crushing and separation technology, the cable granulator can effectively separate copper, plastic and other materials in scrap wires and cables, achieve resource recycling and reduce environmental pollution

Large Profit Margin

Although the production and use of cable granulator has high technical content and threshold, its use can significantly reduce the processing cost of scrap wires and improve the utilization rate of scrap wires. As an important non-ferrous metal raw material, cable granulator has a large market demand and a stable price, which provides a broad profit space for cable granulator entrepreneurship.

Wide Application Areas

In addition to the field of wire recycling, cable granulator can also be used in other fields, such as medical waste treatment, electronic waste recycling, etc., further broadening its market demand.

Environmental Policy Support

As global environmental protection policies continue to tighten, the recycling and reuse of scrap wires and cables has become an inevitable trend. As the core equipment for recycling and processing, cable granulator have received policy support and promotion, and the market demand for cable granulator has further expanded.

To sum up, the demand for cable granulator in the global recycling market continues to grow and has broad development prospects.

2. The development trend of the cable granulator market

At present, the cable granulator market presents the following characteristics:

Technological Innovation

With the advancement of science and technology and changes in market demand, cable granulator technology is also constantly innovating. The new cable granulator adopts more advanced separation technology and an intelligent control system, which improves processing efficiency and recovery rate and reduces energy consumption and cost.

Customized Demand

Different users have different demands for cable granulator, so customized services have become a major trend in the cable granulator market. Manufacturers can provide personalized solutions and customized products based on user needs and actual conditions.

In addition, with the continuous development of the global economy and the continuous growth of new energy, electronic information and other fields, the demand for copper will continue to grow. At the same time, the continuous tightening of environmental protection policies and the improvement of people’s environmental awareness will also promote the continuous development of the cable granulator market. Therefore, the cable granulator market will continue to maintain a prosperous trend in the future.

3. Potential growth opportunities for cable granulator investment

Investing in a cable granulator is an entrepreneurial opportunity with potential and benefits.

The market demand for cable granulators continue to grow, providing entrepreneurs with broad market prospects. As the awareness of environmental protection increases, more and more companies are beginning to pay attention to the recycling of scrap wires.

In addition, the return on investment of cable granulator is very high, and the cost can often be recovered in a short time. Cable granulator belongs to the environmental protection industry and is in line with the national green development policy direction, so it can obtain policy support in the process of recycling. Equipment manufacturers generally provide comprehensive technical support and services to help users solve various problems in the use of equipment.

What’s more, the cable granulator has a high degree of automation, stable operation, and good economic benefits and production efficiency.

Ⅵ. Conclusion

IN SUMMARY, investing in a cable granulator machine is a wise choice for recycling business. Not only can it improve recycling efficiency and profit potential, but it can also reduce environmental pollution and adapt to market demand. If your business involves copper wire recycling, then a cable granulator machine is undoubtedly an investment worth considering.

Related Articles

- How to Maximizing the Copper Recycling Rate of Your Copper Granulator Machine?

- What Should You Consider When Buying a Copper Wire Recycling Machine?

- Components and Accessories for Copper Wire Recycling Machine

- What Should I Pay Attention to When Operating the Copper Recycling Machine?

- How To Make Your Copper Wire Recycling Machine More Durable?