Most advanced Radiator Recycling Machine for copper and aluminum separator

• Patented product invented by BSGH Granulator.

• With the most advanced separation technology, the final product metal purity is up to 99.9%.

• Multiple model options to handle different types of radiators and different efficiencies.

• Common radiators • Aluminum clad radiators • Heating Radiators

1st Generation(Current Market Machine), 2nd Generation, 3rd Generation

Best radiator recycling machine solutions

BSGH Granulator offers a complete range of radiator recycling machine and solutions, covering almost every type of radiator on the market. Following 6 models of radiator recycling machines for your reference. You can choose according to your waste radiator type, or if you have special types of radiators, you can contact us directly and we will recommend the most suitable machine based on your raw materials.

For our radiator recycling machine, we have radiator shredder recycling line and single radiator stripper machine, here, you can find all types of radiators recycling solution in this page.

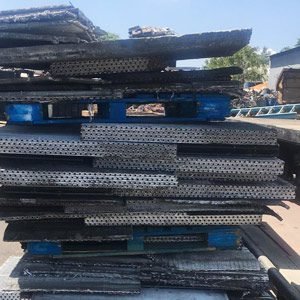

aC radiator recycling machine for sale

Looking for an efficient way to recycle used radiators?

Our AC Radiator Recycling Machine is specially designed to process radiators from scrap cars, air conditioners, and water tanks, heating radiators, aluminum clad radiators. It separates copper, aluminum, and iron with high precision and minimal waste.

We provide complete, end-to-end solutions tailored to your recycling needs — whether you’re upgrading your facility or launching a new project. With easy operation, high recovery rates, and reliable performance, our machines help you maximize profits while staying environmentally responsible.

- Most complete solutions

- Professional invent patent for these machines.

- We can custom any size for you.

- Any kinds of radiators is ok.

- 98% china market share at least.

solutions for different types of radiator recycling machine for sale

Our radiator recycling machines are engineered for professional metal recovery operations, delivering high separation efficiency, stable performance, and scalable capacity. Whether you are processing copper–aluminum radiators from automotive air conditioners, household AC units, or tackling more demanding materials such as flat radiators, round radiators, and iron-clad radiators from refrigerators and heating systems, our equipment ensures:

- Precise separation technology for maximum copper, aluminum, and iron recovery

- Heavy-duty construction for continuous, industrial-grade recycling with minimal downtime.

- Flexible processing capability, supporting diverse radiator structures and mixed materials.

- Optimized yield and profitability, reducing manual labor while increasing output, the biggest capacity can upto 5T/H.

- Expandable system design that scales with production requirements, from small recyclers to large facilities.

By investing in a high-performance radiator recycling machine, you gain a long-term solution that combines efficiency, durability, and profitability, ensuring competitive advantage in the recycling industry.

- Processing capacity about 3T/Day.

- Can directly process 1-2 layer radiators.

- It can process waste radiators with copper tube center distances of 19mm, 21mm, and 25mm, we can customize for your specific needs.

- Processing capacity about 4T/Day.

- Also can directly process 1-2 layers of radiators.

- Suitable for copper tube center distances of 17.5mm, 19mm, 21mm, 22mm, and 25mm, also supports customization.

- Processing capacity 3T/H.

- A pre-shredder + fine crusher + 2 air separator beds + 2 magnetic separators + dust collection system.

- Separation rate can reach 99%.

- suitable for all kinds of AC radiators.

BS-ACP1300 powerful Radiator Recycling machine

- Processing capacity about 5T/H.

- Power: 245.7KW.

- Equipped with a bottom-screw crusher with the high-speed breaking principle, reducing the copper cladding situation and the loss of copper and aluminum.

- Specially designed to separate aluminum foil and iron tube of aluminum clad iron radiator, not fit for copper tube.

- It can process aluminum-clad iron radiators with inner diameters of 20mm, 22mm, 25mm, and 27mm, also can custom for you.

Heating Unit Radiator recycling Machine

- It can process almost all kinds of home-finned radiators or heating radiators.

- The sharp blades can quickly cut the radiator shell and separate the metal tube inside.

- Suitable for iron tube or steel tube, not fit for copper tube.

Unlock the Hidden Value in Scrap Radiators

Scrap radiators are a valuable source of non-ferrous metals like copper, aluminum, and iron. However, their true profit potential remains locked until these materials are effectively separated. BSGH Granulator’s advanced radiator recycling systems are engineered specifically to solve this challenge. Our technology precisely separates copper, aluminum, and iron, turning your scrap into a consistent revenue stream while promoting a circular economy.

Tailored Solutions for Every Operation:

For Smaller Volumes: Our compact small radiator recycling machines efficiently process units from cars and household appliances, delivering cleanly separated copper or iron tubes and aluminum foils, ready for the market.

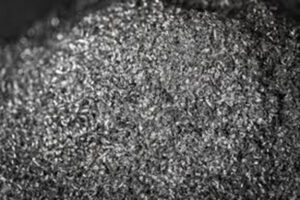

For High-Capacity Facilities: Our industrial-grade radiator recycling lines granulate the separated metals into high-purity copper rice, aluminum granules, and iron fragments, maximizing your profit margins on a larger scale.

By choosing BSGH Granulator, you’re not just recycling—you’re investing in smarter resource recovery and significantly boosting your bottom line.

Why us?

With over 30 years in the copper recycling industry, BSGH Granulator is a trustworthy scrap radiator recycling machine manufacturer with more than 70% market share in China. Our copper and aluminum separator machine features advanced technology for efficient separation and higher recovery rates with patent, maximizing metal resource value, occupy 97% market share in China. we are original designer for radiator stripper machine, so we can custom for your different radiator size, trust BSGH Granulator, help you gain more profits.

Patent and high-quality machines

As the inventor of the radiator recycling machine, we hold an exclusive patent and lead the industry with advanced craftsmanship and proven technology. Our machines deliver exceptional performance with minimal copper loss, achieving a 99.99% recovery rate. Built for durability, they ensure stable operation for over a decade under normal use.

Personalized customization service

Because of different radiators have many different size and shapes, so we support customizing copper tube center distance, motor brand, motor power, blade material, machine color, etc. to meet your special recycling needs.

Perfect after-sales service

We provide comprehensive perfect services to help you use the machine better. From equipment installation and operation training to daily maintenance, we have detailed instructions and provide online guidance. In addition, we provide 1 year warranty and lifetime online quick response service.

Global Market Inspection

Our radiator recycling machines have been exported to more than 80 countries including the United States, the United Kingdom, Italy, Japan, Thailand, etc., and have won unanimous praise from customers all over the world. You can feel confident in your decision to partner with us, and we will do our best to provide you with the best machines and services.

welcome to our factory

radiator recycling machine -HK customer case

One of our customers from HK, he buys our machine many years ago from the first generation, after he earned back his machine cost in 15 days; in 2020, he bought another set of our BS-ACP1000 for 2nd generation, already used so many years, from the small workshop to big recycling factory, we appreciate it so much for our customer’s trust.

CE certificate

All our copper wire granulators pass CE certificate, you can rest assured to export to Europe.