vertical dual shaft shredder for sale

+ Wide Material Compatibility: Handles plastics, pipes, sheet metals, scrap metals and composites(fiberglass, resin) — your all-in-one size reduction solution; also fit for your extra long materials.

+ Unique Vertical Blade Chamber Design: No heavy lifting, easy loading — cuts effort while boosting efficiency.

+ Fully Customizable to Your Needs: Blades (material/thickness/quantity), motor (power/brand), voltage, color — tailored to your needs.

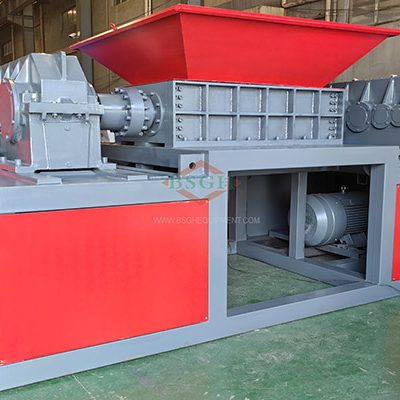

vertical dual shaft shredder with front-feed design

Our vertical dual shaft shredder is built for sites where space is limited and materials are oversized. The innovative front-feeding system makes feeding easy, even in facilities with only 3–4 meters of ceiling height. Unlike horizontal shredders, there’s no need to lift heavy loads such as wind turbine blades or composite blocks to high positions. This reduces labor effort, cuts operating costs, and improves safety.

With higher efficiency and lower feeding costs, you can process more material, maximize profits, and keep operations running smoothly.

Hot sale vertical dual shaft shredder

All of our vertical dual shaft shredders come equipped with dual high-torque motors working in combination with precision-engineered reducers. This heavy-duty drive system delivers stable, powerful force, making it easy to handle even the most demanding materials. Beyond the standard design, we also provide customized solutions. Depending on your raw material—its size, type, and composition—as well as your target capacity, we can adapt the shredder to match your production needs. Our technical team will guide you through the options and help you choose the model that fits your operation best.

MS-D300 vertical dual shaft shredder

- Motor: 4KW*2

- Blade: Φ180*15

- Axis: Φ60*6

- Size: 1540*600*1450

MS-D600 vertical dual shaft shredder

- Motor: 11KW*2

- Blade: Φ220*20

- Axis: Φ110*6

- Size: 2500*1100*1800

MS-D800 vertical dual shaft shredder

- Motor: 37KW*2

- Blade: Φ350*40

- Axis: Φ180*6

- Size:3400*1600*2100

BS-D1200 vertical dual shaft shredder

- Motor: 75KW*2

- Blade: Φ500*60

- Axis: Φ230*6

- Size: 4500*2200*2400

BS-D1400 vertical dual shaft shredder

- Motor: 90KW*2

- Blade: Φ550*70

- Axis: Φ270*6

- Size: 5600*2300*2800

BS-D1600 vertical dual shaft shredder

- Motor: 110KW*2

- Blade: Φ600*80

- Axis: Φ300*6

- Size: 6200*2530*2800

BS-D1800 vertical dual shaft shredder

- Motor: 132KW*2

- Blade: Φ650*100

- Axis: Φ320*6

- Size: 6500*2530*2800

BS-D2000 vertical dual shaft shredder

- Motor: 160KW*2

- Blade: Φ700*100

- Axis: Φ370*6

- Size: 7400*2800*3000

vertical dual shaft shredder for Diverse Raw Materials

Our versatile vertical dual shaft shredders can process a wide variety of materials, from paper, plastic waste, wood pallet, tire, HDPE pipe to scrap light metal (copper, aluminum), and composite materials. Achieve a uniform output size and stable, high efficiency for all your recycling and waste reduction needs.

How does vertical dual shaft shredder work?

Watch our BS-D1800 vertical blades shaft shredder efficiently processing long, entangled HDPE pipes, showing exceptional operational stability throughout the entire process, with minimal vibration and low noise levels.

As you can see, the feeding and shredding process is continuous and smooth, specifically engineered to handle such challenging materials without hesitation, jamming, or unexpected downtime, indicating the reliability and robust performance BSGH Granulator builds into every machine.

Choose Us, helps you get twice the result with half an effort

Why choose our vertical dual shaft shredder?

As a leading shredder machine brand, BSGH Granulator provides professional and efficient shredding solutions for a wide range of waste. Our distinct vertical shaft crusher, combining strong power, stability, durability, and intelligent control, is particularly recognized and trusted by industrial users in the European and American markets.

Pre-Screened Sieve

Beneath the rotors assembled with a screen, ensures only smaller than the required size particles exit the chamber guarantee a consistent output size for downstream processing.

detachable design

The detachable design makes the inspection, replacement, and maintenance of key components such as blades and axes simple and convenient, greatly reducing daily maintenance costs and time.

Twin-shaft structure

The dual-shaft shearing system easily handles elastic and entangled materials, keeping the shredder running smoothly and boosting overall throughput.

Auto-Reverse Function

If the machine encounters hard or oversized materials, the shafts automatically reverse to clear the jam—protecting the system and ensuring continuous, zero-downtime operation.

Let's Work

How to Get Vertical Dual Shaft Shredder from us

Send us your inquiry and we will help you through the entire ordering process. Don’t worry, our professional staff can help even first-time importers have a smooth purchasing experience.

Inquiry and Consultation

Send us pictures of your raw materials, and we will recommend the most cost-effective model for your needs.

Customization & Quotation

If you have special requirements for machine blades, motors, and other parts, contact us freely for the lowest price.

Order Confirmation & Manufacturing

After vertical dual shaft shredder model is confirmed, we will arrange production immediately after receving your 30% deposit of the machine price.

Delivery & After-Sales Support

Once the shredding machine is ready, we will send you a test video for check, and ship it asap after receiving the remaining 70% payment. We also provide a 12-month warranty and lifetime online quick response service.

Positive Feedback on Our Vertical dual Shaft Shredder

Don’t just take our word for it — see what our clients have to say! Below are genuine reviews from businesses across Europe and North America who are using our vertical shaft shredders to enhance their recycling processes. Their experiences highlight the reliability, efficiency, and durability that define BSGH Granulator equipment.

FAQ

What kind of output size can I expect from vertical dual shaft shredder?

For output size we can customized for you according your different needs, for details, you can consult our sales manager.

Can your vertical dual shaft shredder be integrated into a full production line?

Absolutely. It can be combined with conveyors, sorting systems, crushers, and separators for a fully automated recycling line.

What safety features are included?

The system comes with overload protection, emergency stop, safety locks, and a CE-certified control system to ensure safe and reliable operation.

How is the vertical dual shaft shredder machine shipped? Where should I pick it up?

We usually ship the machine to your nearest port, and destination port agent will send you notification for arrivial, you can prepare documents and pick it up after making custom clearance after machine arrives at the port.